Boom in relationships and quality of visitors. This is the reward for Fabbri’s confidence in the events in presence and in Meat Tech 2021

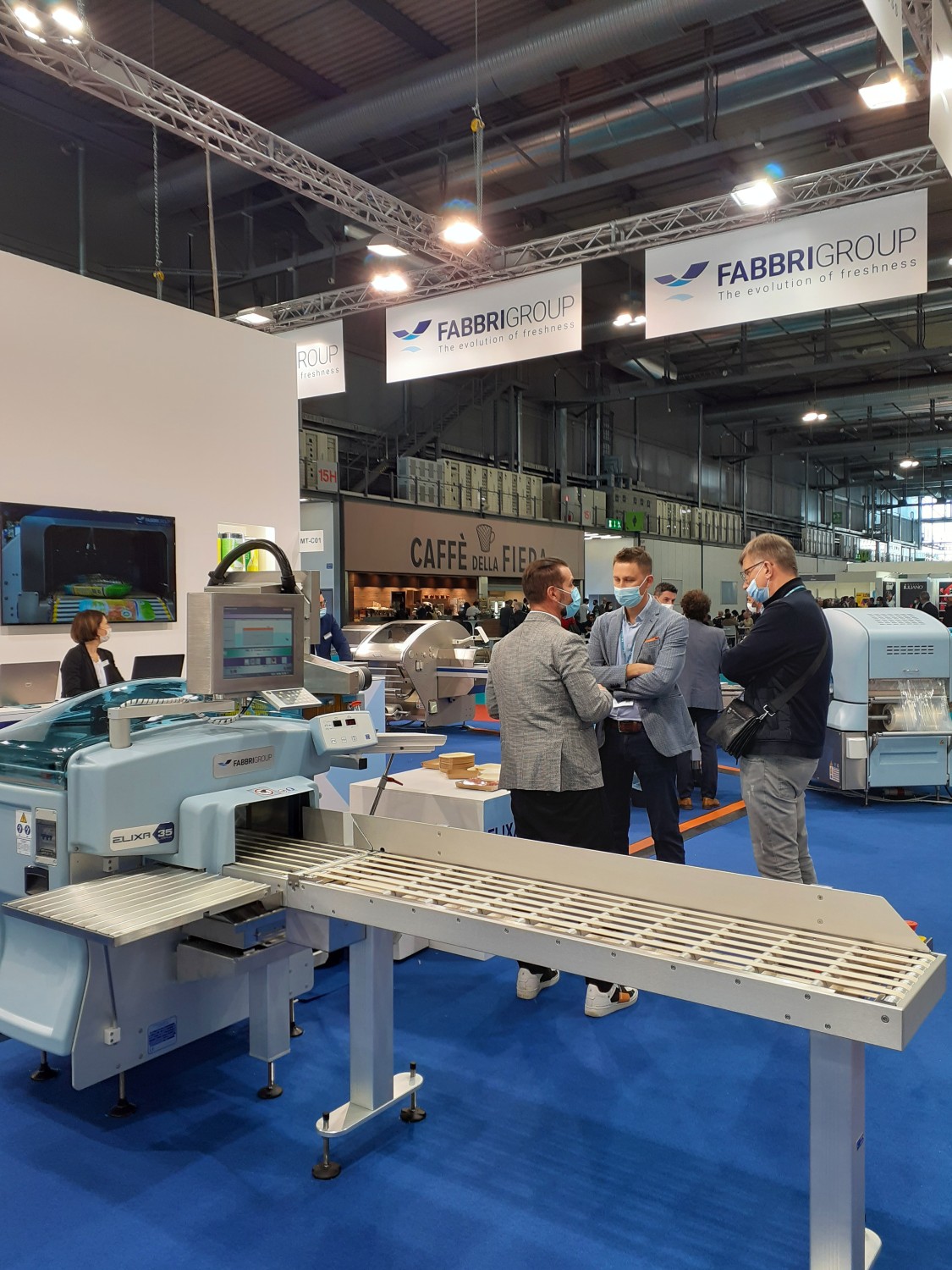

An exhibiting area of 250 m², an offer that ranges from wrapping machines, to tray-sealers, to stretch and barrier films, and a highly competent and fast after-sales and spare parts service all over the world: this is the recipe for Fabbri Group’s success at Meat Tech 2021. During the event, the staff welcomed numerous entrepreneurs, managers and technicians from the meat, cold cuts and ready meals sector to the Fabbri stand.

Worth mentioning, were also the educational meetings for university students within the “Fabbri Academy initiative”, during which the Fabbri technicians explained the advantages of food packaging against food waste and how some of the most popular packaging machines on the market, designed by Fabbri, work.

Undisputed stars of the event were the “CAVECO” line of automatic, semi-automatic and manual tray-sealers for MAP and SKIN packaging, and the multi-award-winning “Nature Fresh”, the certified compostable stretch film already produced in hundreds of tonnes and tens of thousands of reels, with millions of packs already been sent to market.

“The figures are in line with those of the previous Meat Tech edition, which was by no means a foregone conclusion if we consider the pandemic situation that has been preventing companies from developing relationships and business in attendance at trade fairs and events so far, and which is still not fully resolved - comments Stefano Mele, CEO - The industry wants to invest in high-performance, yet sustainable solutions: throughout the show, we noticed a clear increase in the quality of visitors, who, with clear ideas and ambitious projects, specifically sought Fabbri’s support for their implementation. We were thus able to reconfirm our established business relationships and, at the same time, see the emergence of several new business opportunities.”

Through non-stop demos, Fabbri Group illustrated the most innovative packaging solutions, including:

➔ FABBRI HYBRID – Unique in the world, the “Hybrid” Fabbri wrapping machines can use trays and stretch films in any material (traditional, bio-based, compostable), adapting production with extreme flexibility to any requirement from customers without additional costs or slowdowns. By popular demand, many demos were made with NATURE FRESH neutral and printed, the first stretch film in the world for automatic and manual packaging with domestic and industrial compostability certification (EN 13432). At the “Packaging Speaks Green Pocket” conference, the host speaker Stefano Mele announced the forthcoming launch of “Nature Lid”, the barrier film by Fabbri with similar compostability characteristics.

➔ ELIXA LIBRA – Developed in collaboration with Espera-Werke, these integrated wrapping machines feature top/bottom labelling, automatic format recognition, and use a single width film with consequent savings on materials.

➔ GAMMA, MAGIC 2.0, STORM (CAVECO) – Among the most representative models of the more than 15 different automatic, semi-automatic and manual CAVECO tray-sealers MAP and SKIN packaging, Gamma, Magic 2.0 and Storm fully meet the needs of the meat sector by offering compactness, versatility and productivity. The automatic CAVECO tray-sealers can also be integrated into a complete line, for which CAVECO itself can supply all the necessary components.

➔ Fabbri Group’s wide range of STRETCH and MAP FILMS – Used in both retail and industry in neutral or printed form, they are ideal for packaging red and white meat, minced meat, hamburgers and other meat-based products, cevapcici, ready meals and vegetable proteins.

Subscribe to our news in social networks and newsletter:

Share our publications on your social networks:

Source: Unipack.Ru

Printable versionAll press-releasesAdd press-releaseSubscribe to News