Ixapack Global introduces its two new solutions

In order to enlarge our range of solutions and to respond to numerous requests from our customers, we have developed two new machines, meeting different needs: an automated Tray Erector and a Case Former.

TRAY ERECTOR – ITF

The iXAPACK GLOBAL automated Tray Former is an equipment that completes our range of overwrapping solutions amongst cartoning, case packing, palletizing systems…

This Tray Erector can handle up to 30 trays per minute, ideal for low volume productions.

Once flat blanks are loaded in the magazine, trays are erected, sealed via Hotmelt gluing system and ready for output palletizing or manual handling. Erected trays can be conveyed to a manual or robotic loading unit.

4-glued corners tray, dihedral, stackable trays, this equipment is geared up for multi-format production for greater flexibility. An intuitive HMI is also available, where the different settings are displayed.

Robust and reliable machine not requiring loads of maintenance, this automated Tray Erector is easy-to-use, ergonomic within a small footprint, enabling an easy integration in your production lines.

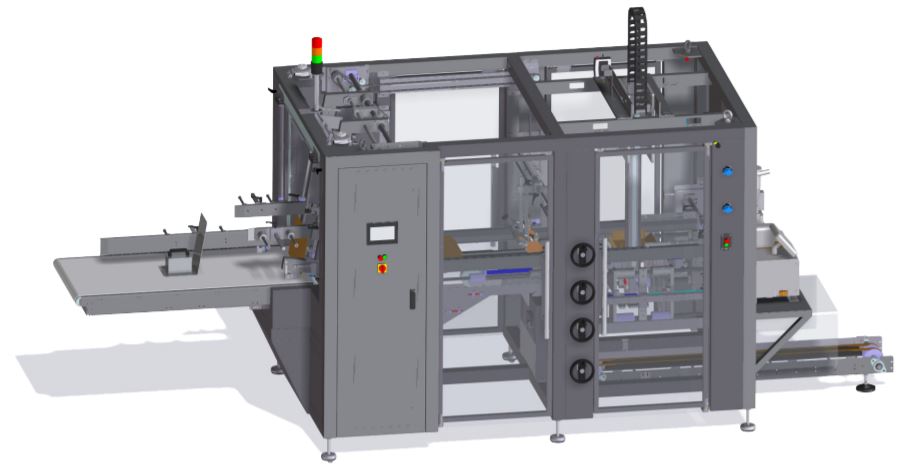

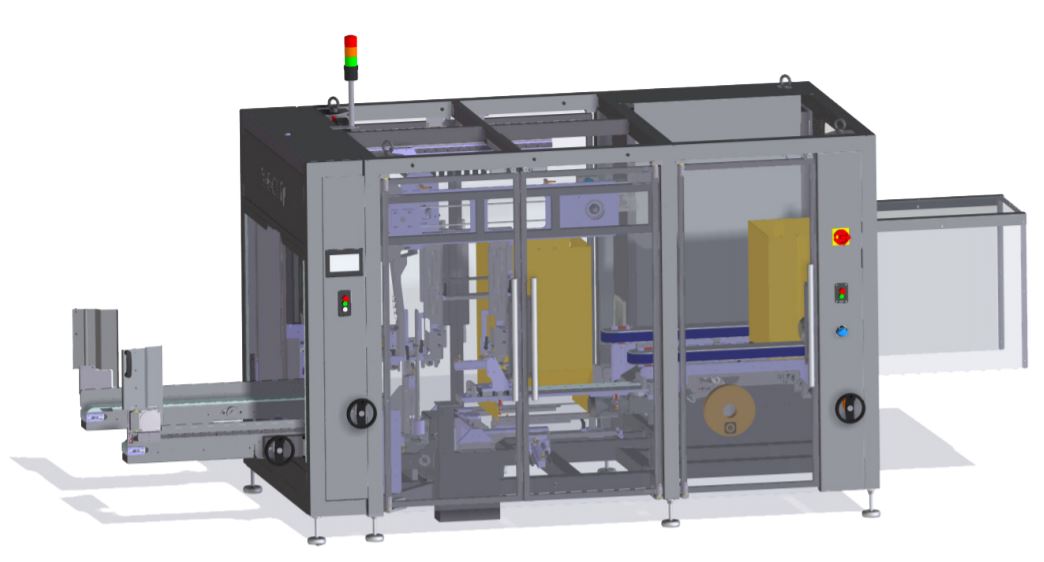

CASE FORMER - ICF

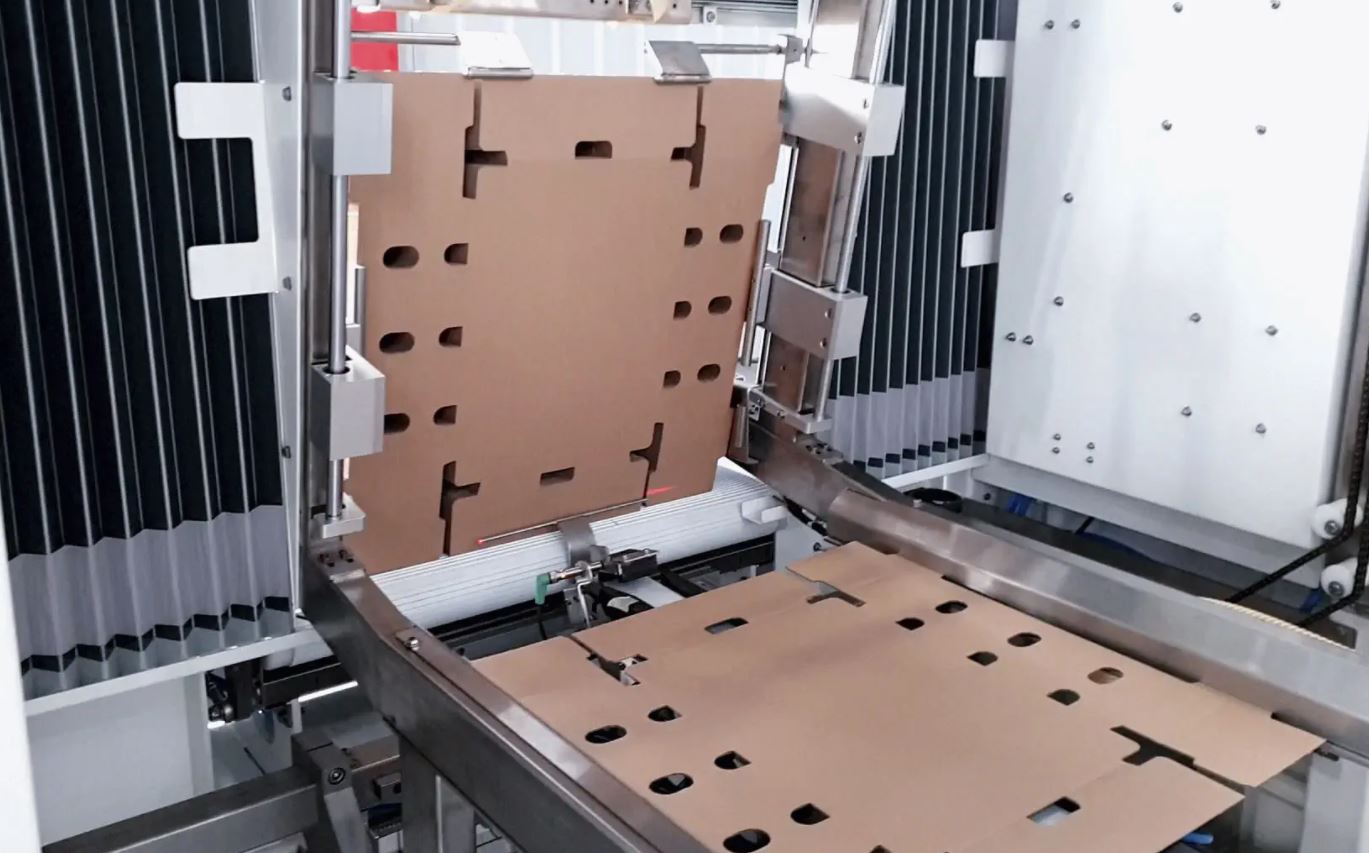

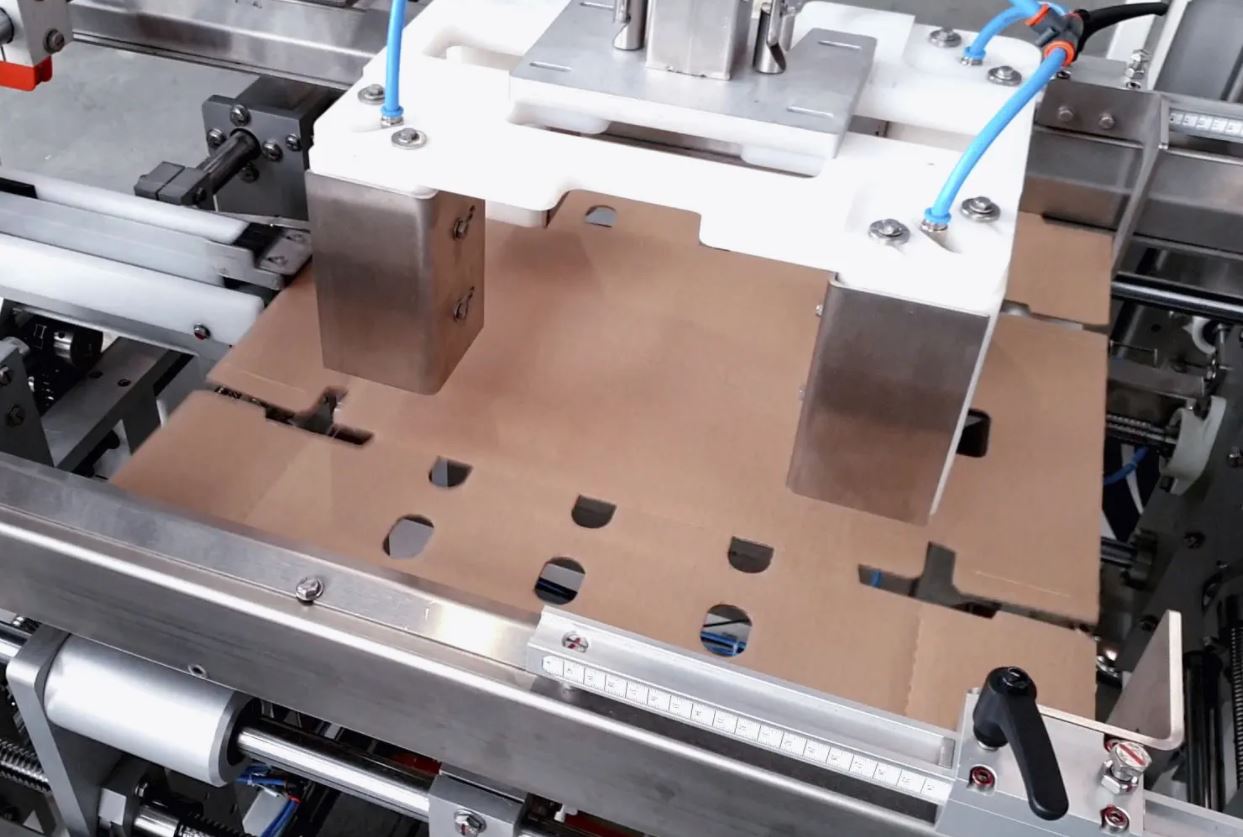

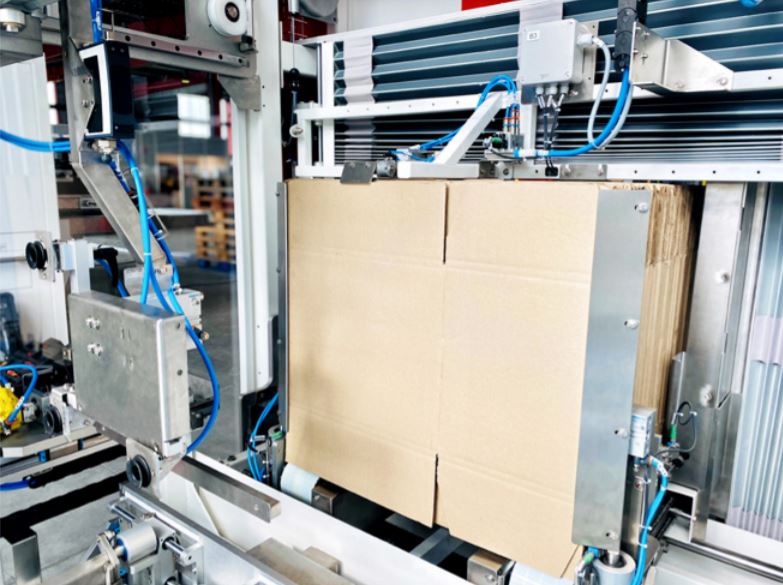

The ICF RSC Case Former allows, within one single equipment, the unstacking of pre-glued Regular Slotted Packaging cardboard blanks, their forming and bottom sealing by adhesive tape.

This equipment, entirely developed by our team, is ideal for productions which do not require large process volumes, with a speed of up to 15 cases per minute. This case erector has a small footprint, enabling easy integration into workshops.

Designed for multi-product packaging, its flexibility allows it to manage different blank sizes, with an intuitive HMI for a quick handling of the equipment.

Once the cases have been formed, they are directed to a filling module, which can be robotised or manual depending on the volumes handled.

Standard equipment but customisable, 3 magazine versions are available: on the front, left or right side of the machine. Its structure is also adapted to operators, since the blanks magazine and machine output are located at an optimal working height.

Subscribe to our news in social networks and newsletter:

Share our publications on your social networks:

Source: Unipack.Ru

Printable versionAll press-releasesAdd press-releaseSubscribe to News